One of the biggest operationally expenses in runing a facility is the cost of cooling and drying air. Understanding your facility is key to ensuring that processes run as safely but as efficiently as possible. An energy efficiency audit is an opportunity to get a detailed impartial view of operations and any areas where improvements can be made.

| We approach all engineering audits in the same way, spending time in a facility to gain a deep understanding of your processes and equipment and then applying our many years of experience to offer suggestions for improvements to help improve you facilities energy efficiency, without risking compliance. Suggestions can be as simple as minor changes to layouts, to improved personel or material flows, to major overhauls of air handling systems or control philosophies, that result in increased operator comfort levels, and reduced conditioned air wastage. | |

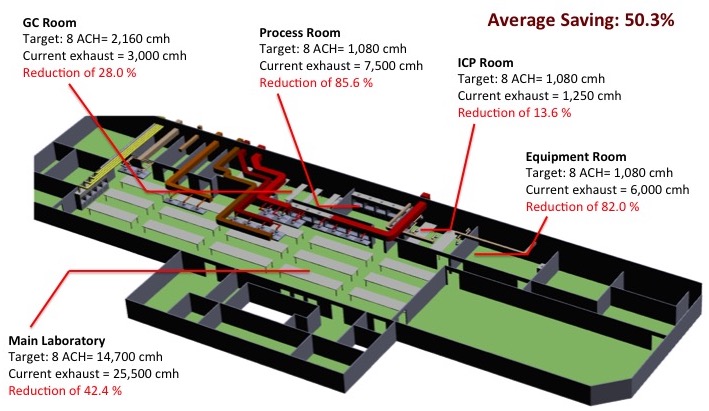

Audit for efficiency We have been working with the Sustainable Energy Association and Sustainable Laboratories Groups of Singapore and the global International Institute of Sustainable Laboratories since 2015 to promote sustainability, and optimise efficiency thoughout our engineered solutions. We have been working with the Sustainable Energy Association and Sustainable Laboratories Groups of Singapore and the global International Institute of Sustainable Laboratories since 2015 to promote sustainability, and optimise efficiency thoughout our engineered solutions. It is common knowledge that laboratories and cleanrooms perfom badly when it comes to energy efficiency but with some tweaks huge improvements are possible. With simple upgrades and retrofits we have seen reductions in energy usage in high throughput labs of almost 40% with no down time. The same approach and solutions can also be applied to new facilities. In addition to an immediate reduction in operational costs, by running systems optimally, service and maintenance requirements can also be reduced. The life span of motors, filters, chillers and dehumidifiers can also be substantially increased. | |

Audit for safetyIf equipment isn't running within design limits it often results in unsafe conditions. For example, when there is too much or too little air in a laboratory, fume cupboards may not provide the correct conditions for safe usage. By optimising system capacities, comfort levels can also be improved; lower noise levels, and more accurate control of temperature and humidity, are all possible. A safe and comfortable team is a happy team. |

If you would like more information, please "Get On TRAQuE" and contact us.