Pharmaceutical regulations require that organisations have documented evidence that their temperature controlled environments, chambers and systems are both calibrated, and meet predetermined uniformity criteria. This is where our temperature mapping services come into play.

| Our experience in temperature mapping is extensive, and we have executed and lead multiple large scale thermal mapping projects. Our team has experience working with all the major brands of instrumentation and data-loggers. | |

Studies can be performed on empty or loaded chambers, and at different times of year to handle seasonal variations (e.g. Winter-Summer, or Wet-Dry Seasons). We have experience mapping:

| |

| We directly represent Anville Instruments and Temprecord, two of the leading, and most cost-effective data-logging solutions for thermal mapping. We can map your environments, from -80°C freezers, to +350°C depyrogenation ovens. As well as temperature, we can also monitor related parameters as part of the studies, including Humidity, CO2, and Pressure. | |

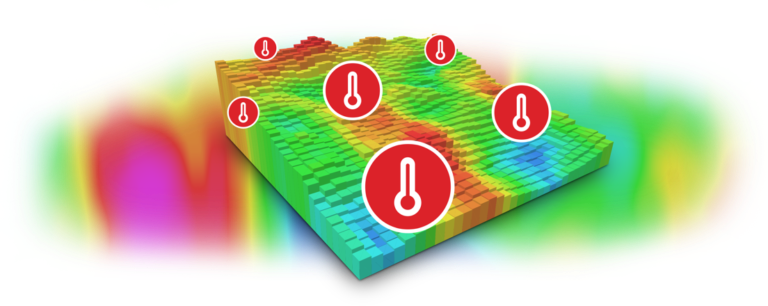

| Our systems and software allow us to visualise your data, and identify hot and cold spots at a glance, helping you to adjust set-points, fans speeds, or utility supplies to achieve your desired acceptance criteria. We utilise our single-use loggers to help with your shipping validation and routine monitoring studies, giving you and your customers assurance that the product remains under its controlled conditions at all times of its journey. | |

| Our team can help you to plan your mapping studies, developing thermal cycles and checking and optimising their performance, so that your systems run efficiently and cost-effectively. We can help you to draft your qualification protocols, in accordance with the latest guidelines and industry standards. We can execute the protocols, including all activities relating to instrument pre-calibration and verification, load set-up and configuration, device placement recovery, and post-execution strip down, calibration verification and analysis of data, and finally, we can write your summary reports. We can also execute in-use tests, such as Door Opening, Power Failure, and Alternative Power Supply Testing. | |

| We can provide complete, validated, environmental real-time monitoring solutions. Using the TAD System, we can set up a complete networked solution, providing data acquisition, reporting, and remote alerts, to ensure your critical environments remain safely within specification. |

If you would like more information, please "Get On TRAQuE" and contact us.